DGS80

Specifications

Details

Rugged incremental encoder with large hollow shaft diameters

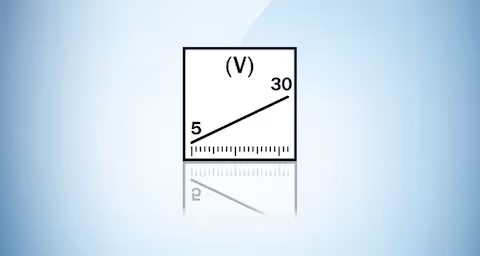

The DGS80 is an incremental encoder with large hollow shaft diameters up to 42 mm. It can be used in countless industrial automation applications. Combined with the many connection options of the DGS80, its supply voltage range of 5 V to 30 V facilitates integration into most control systems. The incremental encoder is characterized by quick and easy installation: This is made possible by its compact design, the clamping ring for speedy mounting, the universal stator couplings and the large selection of collets that simplify mounting on shafts of different size.

DGS80 AT A GLANCE

Benefits

-Large hollow shaft diameters and a wide range of collets eliminate the need for special couplings and allow for quick and easy integration into numerous applications

-Easy integration into control systems thanks to large supply voltage range

-Reduction of installation time thanks to the easy-to-mount clamping ring and the stator couplings

-Compact, space-saving design facilitates installation in tight installation spaces

Features

-Pulse per revolution: Up to 8,192

-Housing diameter: 81 mm, diameter of through hollow shaft: 30 mm or 42 mm

-Enclosure rating: IP65

-Communication interfaces: TTL, HTL

-Connection types: M12, M23 and MS male connector and cable

-Collets available as accessories for adjusting to shafts of different size

ADVANTAGES

Can be used anywhere thanks to large diameter

The DGS80 opens up new application options for incremental encoders: It reliably measures the rotation of large motor shafts up to a speed of 3,600 revolutions per minute. This is ensured by the large hollow shaft diameters of the encoder – 30 mm and 42 mm – and its individually adjustable, insulated collets. A cumbersome connection to a smaller encoder shaft is no longer necessary. This means that many applications can be implemented with this encoder, even if space for installing the device is limited.

The DGS80 enables speed feedback from rotating AC motors – and prevents bearing currents with insulated collets

Measuring the speed of conveyor belts and web guide rollers ensures precise control of production processes

The encoder captures accurate data for elevator speed control on the hollow shaft of the AC motor

Flexible integration into countless machine designs

Flexible integration into countless machine designs

The encoder is characterized by excellent compatibility: The DGS80 can be adapted to many different sizes of shaft and measures their rotations up to a speed of 3,600 revolutions per minute. It also features a wide range of connection options. The encoder can also be operated with very different supply voltages. Thanks to its universal design, the DGS80 can be integrated into almost any existing controller system.

Thanks to the wide range of supply voltages from 5 V to 30 V, the encoder is compatible with almost all controller systems

Can be easily integrated into numerous machines and plants via various connection types such as M12, M23 or MS male connector or cable

The temperature range of the encoder extends from –25 °C to +85 °C and covers many industrial applications

Simple and time-saving installation

The DGS80 can be installed in just a few steps, regardless of the machine design. The slotted stator couplings ensure easy mounting of the encoder with high mounting flexibility at the same time. With a clamp ring, the DGS80 can also be quickly attached to hollow shafts. Its small external diameter of only 82 mm enables mounting even when space is at a premium. Thanks to its wide range of supply voltages, the DGS80 can be installed in almost any existing controller system without an upstream voltage regulator.

Slotted stator couplings and collets in various sizes offer great flexibility for mounting the DGS80 on motors and machines

The clamp ring enables time- and space-saving installation of the encoder directly on hollow shafts

Ready for operation in a flash: The DGS80 is easy to install, even when space is limited

With its universal, rugged design and hollow shaft diameter of up to 42 mm, the DGS80 is ideal for AC motor feedback applications and use in mechanical engineering.

View more about DGS80 on main site