Details

Fast and flexible – for inspection tasks that demand high speed

The InspectorP64x is an industrial programmable and configurable 2D vision camera for long-range and high-speed vision tasks. Boasting an image resolution of 1.7 megapixels, an IP 65 housing, and a flexible high-end optical design, it is perfectly equipped to meet demanding automation environments. The application software is fully flexible thanks to the SICK AppSpace development environment, with image processing powered by HALCON and SICK Algorithm Library.

InspectorP64x AT A GLANCE

Benefits

-Flexible optical design and high-power lighting enable high-speed and long-distance setups

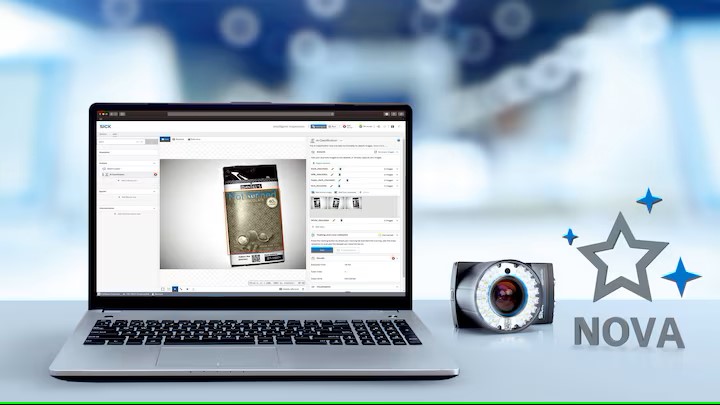

-Easy start for anyone with the pre-installed Quality Inspection toolset of SICK Nova

-Fast, high-resolution programmable 2D cameras ensure maximum performance

-Unique operator interaction possibilities thanks to powerful set of convenience features

-Addition or extension of tool functionality for customized solutions with SICK Nova

-Exceptional programming flexibility in SICK AppSpace or HALCON

-Deep learning available as licensed option

Features

-2D vision sensor with 1.7 megapixels

-Configuration of toolset in a web browser

-Programming of new SensorApps in SICK AppStudio

-Flexible C-mount lenses and integrated illumination

-Laser alignment aid, beeper and feedback spot

-Includes HALCON runtime license and SICK Algorithm Library

ADVANTAGES

Go one step further with SICK Nova

Go one step further with SICK Nova

The Quality Inspection toolset of SICK Nova is included with InspectorP6xx 2D sensors. What does this mean? Machine vision applications are easily handled in a web browser using point-and-click configuration, giving users the freedom to combine tools for image processing and integration as they need. But the functionality does not end there: With SICK Nova, users can download additional Nova tools or develop their own, allowing them to quickly and conveniently extend functionality to fit the application — without limitations.

https://youtu.be/9dk3b6dBXlw

Quickly solve tasks with just the right tools at your fingertips

.jpg)

Choose the right sensor for the application and use the same familiar software.

.jpg)

Rapidly create customized solutions with AppPool downloads or custom development.

Rapidly handle your applications like never before. Add, combine, and customize tools with ease.

Endless possibilities with SICK Nova in AppSpace

Some applications require everything to be programmed from scratch. So it is good to know that behind SICK Nova you have the SICK AppSpace ecosystem. Programming is fully flexible, and you have the support of other programmers and AppSpace developers.

.jpg)

Use SICK AppStudio for developing SensorApps and Nova tools that can run directly on all InspectorP devices.

.jpg)

Combine existing tools with custom code for turbocharged development and flexible re-use in SICK Nova.

.jpg)

The SICK Support Portal is the central community platform of a SICK AppSpace developer and offers access to tutorials, tools, documentation, and FAQs.

Development in SICK AppStudio facilitates complete customization if needed.

Unleash the capabilities of AI-assisted quality control

Unleash the capabilities of AI-assisted quality control

Artificial intelligence makes machine vision tasks easier than ever before. Since the vision sensor is not programmed with manually created rules but instead trained by means of examples, applications can be provided quickly. It also opens up new test functions. When you combine the advantages of AI-supported and rule-based tools, you get promising solution possibilities – regardless how experienced the person operating the automated image processing system is.

Training the AI on the device

SICK Nova provide easy-to-use AI tools that can be taught using examples. Collect, train, and execute directly on the device. Combine with rule-based tools to easily verify known specifications.

.jpg)

AI training using SICK dStudio

SICK dStudio Cloud Service trains AI at scale with optimized inspection accuracy and speed on the sensor. Convenient data management and collaborative annotation make handling large data sets a breeze and makes it possible to take on big projects with confidence.

SICK LifeTime Services

SICK’s services increase machine and plant productivity, enhance the safety of people all over the world, provide a solid foundation for a sustainable business operation, and protect investment goods. In addition to its usual consulting services, SICK provides direct on-site support during the conceptual design and commissioning phases as well as during operation.

The range of services not only covers aspects like maintenance and inspection, but also includes performance checks as well as upgrades and retrofits. Modular or customized service contracts extend the service life of plants and therefore increase their availability. If faults occur or limit values are exceeded, these are detected at all times by the corresponding sensors and systems.

.jpg)

Consulting and design

Application-specific advice on the product, its integration and the application itself.

.jpg)

Commissioning and maintenance

Application-optimized and sustainable ─ thanks to professional commissioning and maintenance by a trained SICK service technician.

.jpg)

Service contracts

Extended warranty, SICK Remote Service, 24-hour helpdesk, maintenance, availability guarantees and other modular components can be individually combined on request.

View more about InspectorP64x on main site