Inspector83x

Specifications

Details

AI-powered quality control made stress-free

Put an end to wasted material or faulty products. Put an end to long setup times or expensive reconfiguration when the product is changed. Put an end to complicated integration or data trapped on the shop floor.

The Inspector83x is designed to make quality control easy and efficient. The cutting-edge AI technology enables non-expert users to rapidly solve vision applications such as quality assurance, defect detection, and sorting directly on the device by simply teaching it by examples.

The high-speed vision sensor provides an easy way to inspect every single part, every detail, every time. Connected, reliable, intelligent – stress-free.

Inspector83x AT A GLANCE

Benefits

-Teach by example with the AI-powered Intelligent Inspection toolset to simplify common machine vision tasks such as classification of parts and anomaly detection

-Easy validation of known specifications with rule-based tools from the Quality Inspection toolset

-Solution for demanding inspection tasks, even at very high process speeds

-Excellent resolution for inspection of medium to large areas in great detail

-Easy and flexible to operate and configure

-Flexible integration into industrial network or PLC

-SICK Nova tool plug-ins for convenient customization of inspections in Lua script

Features

-AI-powered Intelligent Inspection toolset

-Quality inspection toolset

-Quad-core CPU

-Up to 5 megapixels and strong illumination

-Intuitive Web UI

-Dual-port fieldbus and high-speed IOs

-SICK Nova, SICK AppSpace, and HALCON support

ADVANTAGES

Unleash the capabilities of AI-assisted quality control

Unleash the capabilities of AI-assisted quality control

Artificial intelligence makes machine vision tasks easier than ever before. Since the vision sensor is not programmed with manually created rules but instead trained by means of examples, applications can be provided quickly. It also opens up new test functions. When you combine the advantages of AI-supported and rule-based tools, you get promising solution possibilities – regardless how experienced the person operating the automated image processing system is.

Quad-core CPU

The high-speed CPU provides impressively rapid analysis, so that every single part can be thoroughly inspected, even at a high speed.

Training the AI on the device

Inspector83x and SICK Nova provide easy-to-use AI tools that can be taught using examples. Collect, train, and execute directly on the Inspector83x. Combine with rule-based tools to easily verify known specifications.

\

\

AI training using SICK dStudio

SICK dStudio Cloud Service trains AI at scale with optimized inspection accuracy and speed on the sensor. Convenient data management and collaborative annotation make handling large data sets a breeze and makes it possible to take on big projects with confidence.

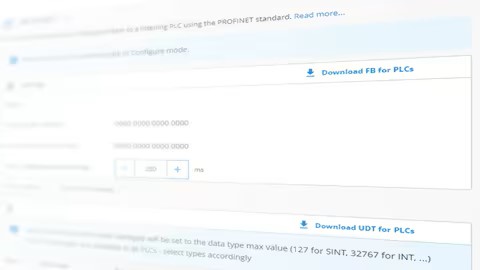

Well connected

Put an end to complicated integration or data trapped on the shop floor. Industrial integration becomes a breeze with dual-port fieldbus capabilities and built-in export of customized PLC configurations for market-leading brands.

The network professional

Dual-port Ethernet fieldbus ports make integration into EtherNet/IP™or PROFINET a breeze. Meanwhile, a dedicated high-speed gigabit Ethernet port provides bandwidth for high-resolution image data, data logging, or TCP/IP integration. An additional USB-C network interface provides a convenient service interface without having to use the operational network.

Easy export of PLC configurations

The built-in export functionality makes it possible to export customized PLC configurations for market-leading brands – with just the push of a button.

.jpg)

Flexible I/O

The up to seven inputs (and up to five outputs) are equipped with queued delay of signals. These can be based on time, or on built-in conveyer tracking using an encoder. This lets the sensor precisely calibrate its image timing and output signals to trigger at the right time as well as to control the ejectors. All of this is possible without the need for additional complex hardware such as a PLC.

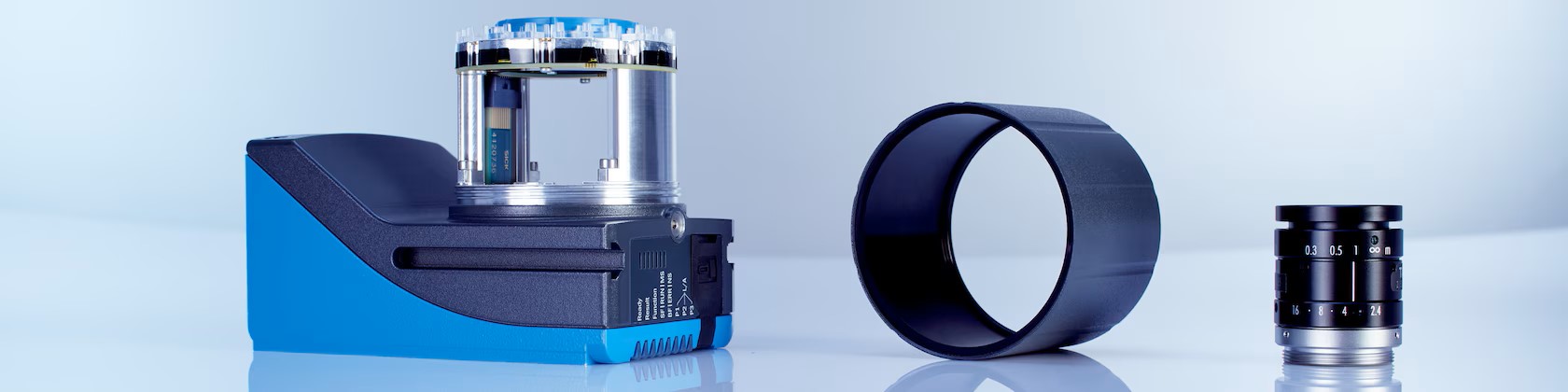

Accessories for demanding tasks

The vast accessory portfolio from SICK grants extensive options for varying needs. The broad range of optics, illumination, filters, cables, and integration accessories suitable for the Inspector83x provide solutions even for challenging applications.

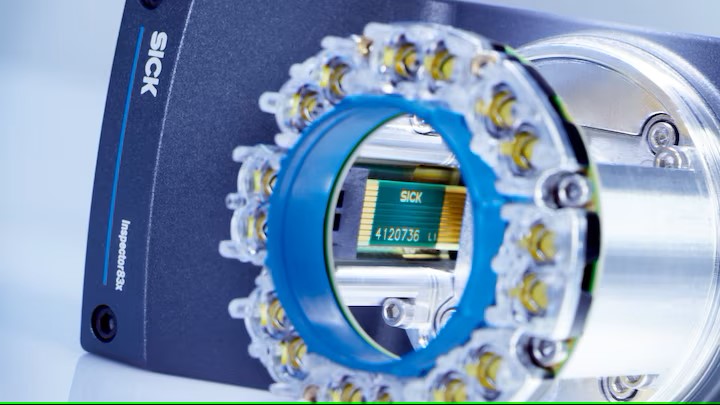

Lenses as key components

Using a standard C-mount threading, the sensor can be ordered with high-quality optics from SICK. Alternatively, it can be equipped with specialized industrial lenses to fit complex inspection needs afforded by third-party lenses.

Application-appropriate illumination

Adding to the flexible system of integrated ring lights, the sensor offers a dedicated port for external illumination. This port can be used to trigger or drive specialized illumination such as backlights or bar lights from the SICK portfolio or from third-party suppliers.

Inspector8xx, the next generation 2D vision sensor

Inspector8xx, the next generation 2D vision sensor

The Inspector8xx-series is designed to make quality control easy and efficient. The cutting-edge AI technology enables non-expert users to rapidly solve vision applications such as quality assurance, defect detection, and sorting. They can do so directly on the device by simply teaching it using examples. The user-friendly web interface eliminates the need for additional software. It also allows for combinations of AI and rule-based tools for optimal solutions in a broad range of applications. This powerful vision sensor enables high-precision inspections at full production speed without the need for external hardware. With variants for compact size or exceptional field of view, versatile connectivity makes integration into existing systems easy. The Inspector8xx-series comes preinstalled with SICK Nova, allowing users to conveniently extend the software's functionality. This also provides a scalability that makes it a safe choice for a cost-effective ownership.

Go one step further with SICK Nova

Machine vision applications are easily handled in a web browser using point-and-click configuration, giving users the freedom to combine tools for image processing and integration as they need. But the functionality does not end there: With SICK Nova, users can download additional Nova tools or develop their own, allowing them to quickly and conveniently extend functionality to fit the application — without limitations.

Quickly solve tasks with just the right tools at your fingertips.

Choose the right sensor for the application and use the same familiar software.

Rapidly create customized solutions with AppPool downloads or custom development.

Rapidly handle your applications like never before. Add, combine, and customize tools with ease.

Further functions to follow – soon!

Further functions to follow – soon!

Color imaging

Color imaging enables inspection of vivid features, suitable for color sorting, defect detection, and quality assurance.

Near infrared (NIR)

The near infrared (NIR) variant does not disturb the surroundings with flashing lights, and it can shield against ambient light when using a NIR-pass filter. For some applications, it even provides a more suitable contrast.

View more about Inspector83x on main site