IME2S

Specifications

Details

Cylindrical inductive safety switch for position monitoring

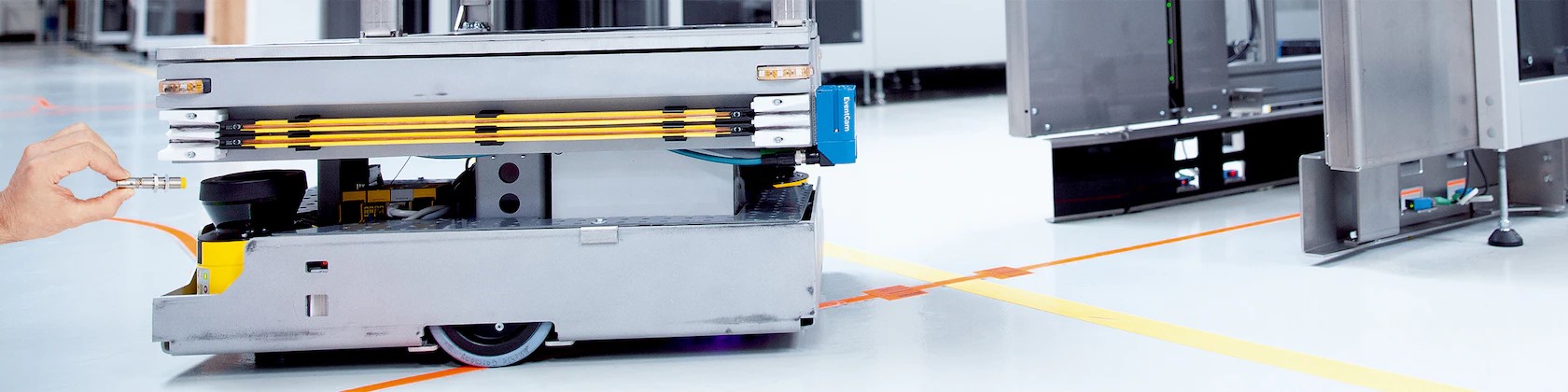

The inductive safety switches of the IME2S product family are used for safe position and area monitoring. Thanks to the very compact design and wide range of connection variants, they offer optimum integration into the machine design. The IME2S switches work without making contact and are low-wear. The inductive safety switches do not require a separate actuator to do their monitoring tasks. On the contrary, they are generally activated by metals, for example on machines. Due to the large response range, the safety switches allow for assembly tolerances, simplifying mounting and adjustment. The IME2S can be connected to a safe control solution via its self-monitoring switching outputs (OSSDs), allowing for high safety with PL d (EN ISO 13849).

IME2S AT A GLANCE

Benefits

-High machine availability thanks to low susceptibility to dirt and moisture

-Long product service life due to low-wear and low-maintenance workings

-Easy integration: Sensors can be mounted to save space thanks to their compact design and do not need a separate actuator

-Fast diagnostics via LED status indicator

-High reliability and precise switching behavior due to proven ASIC technology

-Safe, direct connection to a safe control solution by means of OSSDs

-Easy and flexible connection options thanks to variants with male connector, cable or cable with male connector

Features

-Types: M12 to M30

-Increased response ranges: 4 mm to 15 mm

-Two OSSD safety outputs

-Enclosure rating: IP67

-Temperature range: –25 °C to +70 °C

-Nickel-plated brass housing, plastic sensing face

-Up to performance level PL d (EN ISO 13849)

-Connection variants: M12 male connector, cable or cable with M12 male connector

ADVANTAGES

The highest standard of position and presence detection

The highest standard of position and presence detection

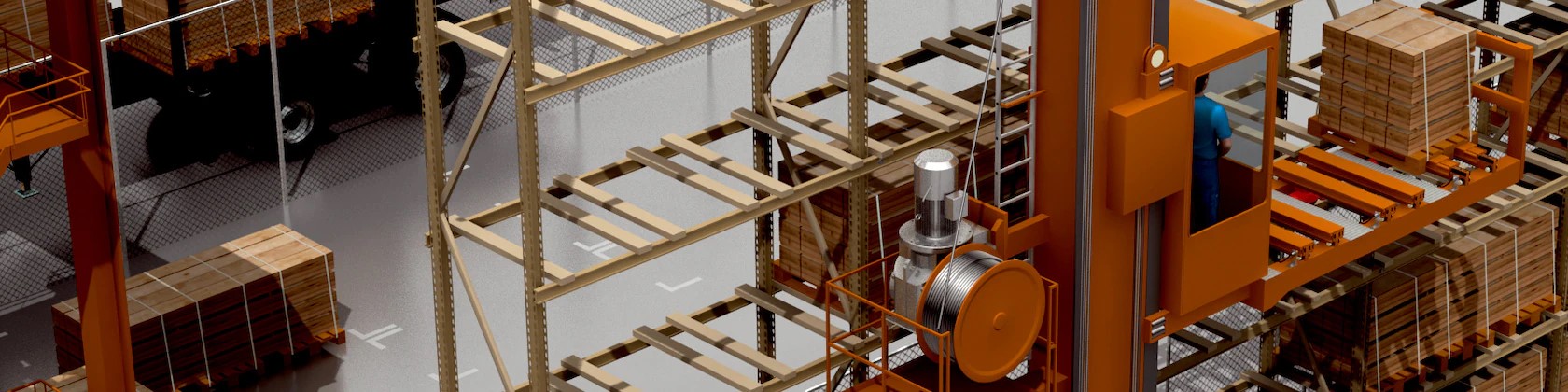

Many machines require safety switches for safe position and presence detection. Thanks to the many variants of the IME2S, it satisfies individual customer requirements with ease. One of its greatest strengths is the precise, non-contact detection of metallic machine parts without a special actuator. Depending on the switch size, it can achieve a sensing range of up to 15 mm.

Many variants with optimal response range

From M12 to M30: The IME2S has the right switch for any drill hole and any required sensing range.

The smallest variant of the IME2S with M12 thread features a unique sensing range of 8 mm and is therefore ideal for detecting moving machine parts in small machines.

The right switch size for any requirement: The IME2S non-contact safety switch

It can be optimally adjusted in just a few steps

It can be optimally adjusted in just a few steps

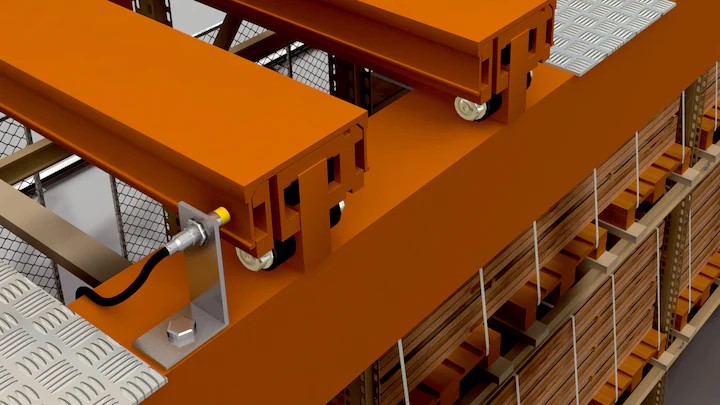

The IME2S can be integrated into the machine with or without a bracket and is easy to adjust. It is also characterized by its high degree of flexibility when it comes to connections. It reliably detects the position of a machine part up to performance level d. Thanks to the two OSSD outputs with test pulses, it reliably detects short- and cross-circuits, therefore ensuring a high level of safety.

Fast adjustment, high tolerance

Thanks to the thread and range of sizes, the IME2S can be quickly integrated into any machine and is easy to adjust. There is no blind spot — and therefore no minimum distance.

The IME2S exhibits high tolerance to deviation. And, just like the IQB2S inductive safety switch, it features non-contact operation and has a very low wear rate.

The IME2S inductive safety switch enables precise adjustment for optimal productivity.

View more about IME2S on main site