Dx50-2

Specifications

Details

The new era in distance measurement

SICK is once again setting the standard in the field of distance sensors with the new generation of Dx50-2 sensors, which provide the perfect combination of measurement performance and size. Based on the patented and improved HDDM™ time-of-flight technology, the new product family supports precise and reliable measuring, with ranges of up to 10 m on black targets and up to 30 m on white targets. The Dx50-2 sensors feature an intuitive display, saving time during installation and commissioning. The high output rate of the sensors delivers up to 3,000 distance values per second for maximum throughput and process quality. The Dx50-2 sensors have a rugged housing and provide reliable operation despite extreme temperatures and harsh ambient conditions. Since the settings for speed, sensing range, and repeatability can be adjusted to meet current requirements, the Dx50-2 sensors can be customized to suit each and every possible application.

Dx50-2 AT A GLANCE

Benefits

-A wide measuring range and a compact housing increase the number of possible applications

-Very high throughput thanks to a high measuring frequency

-Precise and reliable measurement regardless of object color improves uptime and process quality

-Reliably withstands harsh ambient conditions thanks to its rugged design, a wide range of operating temperatures, and ambient light immunity

-Integrated shape comparison for straightforward checking and sorting of objects

-Time savings thanks to quick and easy commissioning by means of intuitive operating structure of the display, easy-teach option

-Full process control with IO-Link from commissioning to maintenance

-Three switching modes provide a simple solution for demanding applications

Features

-Measuring range up to 10 m on black targets and up to 30 m on white targets, compact dimensions

-Output rate up to 3,000/s

-Repeatability: 0.5 mm to 5 mm

-Reliable, patented HDDM time-of-flight technology

-Withstands extreme temperatures from –40 °C to +65 °C thanks to rugged metal housing

-Shape comparison integrated in sensor

-IO-Link, analog and digital output

-Display with intuitive operation and easy-teach option

-Enclosure rating IP 65 and IP 67

ADVANTAGES

Dx50-2 – infinite possibilities – finally available

Dx50-2 – infinite possibilities – finally available

With the measurement technology, which has been optimized in contrast to the Dx50, combined with the most advanced micro-controller technology, SICK is offering a mid range distance sensor which adapts to the given market requirements. The Dx50-2 solves tasks which were previously considered unsolvable.

https://youtu.be/68F7J6yx-Kk

A scanning range like no other and high speed in a compact design with the second generation of Dx50 mid range distance sensors

HDDM and HDDM+ technology

The unique HDDM technology from SICK is a milestone in the development of distance sensor technology. In doing so, the sensor uses the runtime of several laser pulses from the sensor in the direction of the measuring object and back to calculate the distance between the two. This enables stable and gap-free scanning as well as reliable measurement results. And all of this even in dirty, dusty and moist environments.

Higher speed

Measurement and output frequencies of up to three kilohertz enable reliable integration of the Dx50-2, even into very fast processes.

Extended measuring range

Driven by the growing e-commerce business, more logistics hubs are being built worldwide, and ports are being extended or newly built. To face these changes, the measuring range of the Dx50-2 has been increased once again. In combination with the newly-developed optical unit, the sensor enables fault-free positioning of factory and harbor cranes and is perfectly suited for position and distance measurements in classical logistics, to name a couple of examples.

Excellent accuracy

Ever-increasing quality requirements and quicker processes in the automation industry push the distance sensor to the boundaries of feasibility. The Dx50-2 was designed to sustainably meet the requirements on precision and throughput.

The Dx50-2 was developed to increase productivity and is always the right choice when you need a bit higher measurement performance.

The Dx50-2 distance sensors can be used for the most challenging stationary and mobile applications:

The Dx50-2 distance sensors can be used for the most challenging stationary and mobile applications:

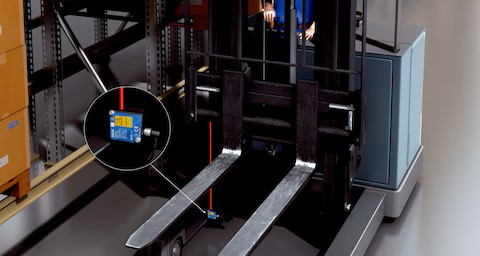

- Positioning of track-bound vehicles, gripper arms and crane systems

- Collision avoidance in ports and intralogistics

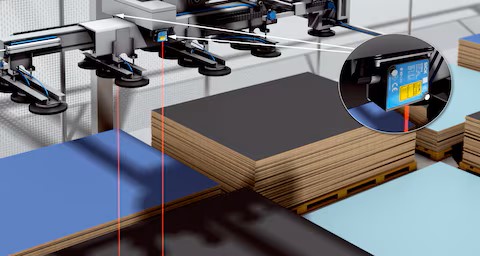

- Quality control and process monitoring in the automotive industry

Indestructible: Slip- and wear-free measurement of stroke height

Essential: Efficient quality control thanks to the smallest light spot geometry and high measurement accuracy

Unbeatable: Location and position determination down to the last millimeter, regardless of the environment

Noticeably more performance for complex tasks in the mid range distance sensor segment.

.jpg) As co-founder of IO-Link, SICK offers one of the broadest IO-Link portfolios on the market. Smart Sensors with IO-Link generate and receive data and information which goes beyond conventional switching signals or measured process parameters. This allows them to create substantial increases in efficiency, more flexibility, and better planning security for predictive maintenance of machines and systems. Benefit from SICK’s extensive experience with a wide range of sensing technologies, and now also in combination with the SIG100 and SIG200 Sensor Integration Gateways.

As co-founder of IO-Link, SICK offers one of the broadest IO-Link portfolios on the market. Smart Sensors with IO-Link generate and receive data and information which goes beyond conventional switching signals or measured process parameters. This allows them to create substantial increases in efficiency, more flexibility, and better planning security for predictive maintenance of machines and systems. Benefit from SICK’s extensive experience with a wide range of sensing technologies, and now also in combination with the SIG100 and SIG200 Sensor Integration Gateways.The IO link allows you to use a simple output signal switching device as a communication interface. This enables quick batch changes and simple commissioning, maintenance and diagnostics.

SICK LifeTime Services

SICK’s services increase machine and plant productivity, enhance the safety of people all over the world, provide a solid foundation for a sustainable business operation, and protect investment goods. In addition to its usual consulting services, SICK provides direct on-site support during the conceptual design and commissioning phases as well as during operation.

The range of services not only covers aspects like maintenance and inspection, but also includes performance checks as well as upgrades and retrofits. Modular or customized service contracts extend the service life of plants and therefore increase their availability. If faults occur or limit values are exceeded, these are detected at all times by the corresponding sensors and systems.

.jpg)

Consulting and design

Application-specific advice on the product, its integration and the application itself.

.jpg)

Commissioning and maintenance

Application-optimized and sustainable ─ thanks to professional commissioning and maintenance by a trained SICK service technician.

.jpg)

Service contracts

Extended warranty, SICK Remote Service, 24-hour helpdesk, maintenance, availability guarantees and other modular components can be individually combined on request.

View more about Dx50-2 on main site