Roller Sensor Bar

Specifications

Details

Flexible conveyor belt sensor for detecting irregular leading edges

The Roller Sensor Bar conveyor sensor is designed to be mounted between rollers and is an elegant, simple solution for reliable detection of objects with irregular leading edges. Sensing performance is optimized through the ability to configure length and beam spacing to the mm. By mounting the Roller Sensor Bar between the rollers, object catch points can be removed thereby decreasing conveyor downtime due to jams. The spring-loaded assembly of the Roller Sensor Bar, which can be mounted in the factory rather than in the field, decreases installation costs by more than half. Commissioning costs are reduced by eliminating the need to teach and align the sensor.

Roller Sensor Bar AT A GLANCE

Benefits

-Reduce conveyor downtime due to false switchings on background-objects

-Optimize sensor performance by configuring beam spacing to the mm

-Increase detection area across the entire conveyor bed by removing blind zones on the near and far side of the conveyor

-Significantly decrease installation costs with a tool-free installation using a spring-loaded end cap

-Eliminate the need for sensor alignment and teaching with factory preset sensing range

Features

-Precise detection of leading edges

-Outstanding ambient light immunity

-Easy installation

-Housing length: 200 mm to 1,200 mm (7.87" – 47.24")

-Beam separation: 50 mm to 200 mm (1.97" - 7.87")

-Number of sensing points: 2 to 8

ADVANTAGES

Easy and quick installation with spring-loaded mounting

Easy and quick installation with spring-loaded mounting

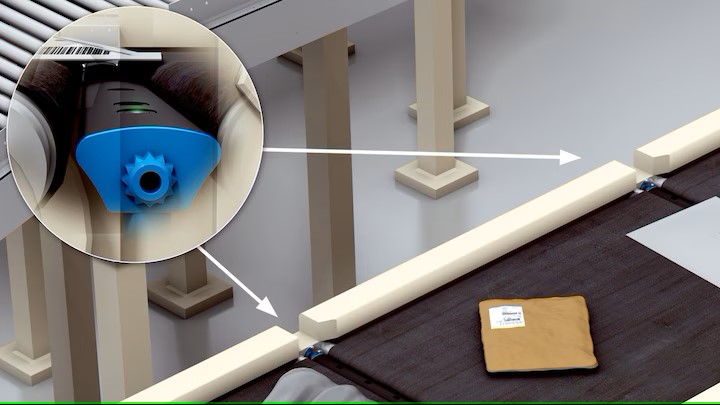

Reduce installation time by up to 30% by taking advantage of the Roller Sensor Bar’s spring-loaded end cap for seamless integration into the conveyor side channel using standard mounting brackets. Decrease installation costs by pre-mounting the sensor in the factory, thereby reducing field labor costs.

Flexible mounting options offer quick and easy integration into roller conveyors, flexible conveyors, live roller conveyers, between belted conveyor sections, and into automated storage and retrieval systems

The self-centering spring-loaded mounting mechanism ensures a quick commissioning experience by eliminating the need for installation tools and added accessories

Performance for individual applications

Performance for individual applications

Optimize the conveyor sensor’s performance by selecting a Roller Sensor Bar configuration that is designed for application requirements. The Roller Sensor Bar reduces blind zones on either end of the conveyor by offering housing lengths between 200 mm-1200 mm (7.87" – 47.24"). Configuring the length of the sensor allows for integration into many conveyor types. Performance is configured by selecting a beam spacing between 50 mm and 200 mm (1.97" - 7.87") to detect poly bags, jiffy packs, boxes, totes, and pallets. Mount the sensor between rollers or belted sections to detect objects between conveyor sections and in transfer zones.

Optimize sensor performance based on application needs: the Roller Sensor Bar accommodates between 2-8 sensing points and beam spacing between 50mm – 200 mm (1.97" - 7.87"). Remove blind zones on the near and far side of the conveyor bed by selecting a beam spacing which meets minimum detectable object requirements.

Seamless integration into conveyor control panels with 10 catalog connection types and 9 standard cable lengths

Mounting of the Roller Sensor Bar between belt sections

Precise leading edge detection and object overhang detection to decrease conveyor jams and increase efficiency

Eliminate the need to qualify multiple sensing solutions by leveraging the Roller Sensor Bar, which is configured to detect distances between 200 mm and 1200 mm (7.87" – 47.24") for a variety of conveyor widths.

Reliable sensor technology

Reliable sensor technology

Equipped with excellent ambient light immunity, the Roller Sensor Bar increases throughput by reducing false trips on objects in the background.

Reduce conveyor downtime by decreasing false detections on objects in the background using the Roller Sensor Bar’s ambient light immunity and pre-programmed sensing range

No ingress of dust, and impervious to water while cleaning due to the Roller Sensor Bar’s IP67 rated housing

View more about Roller Sensor Bar on main site