RAY26 Reflex Array

Specifications

Details

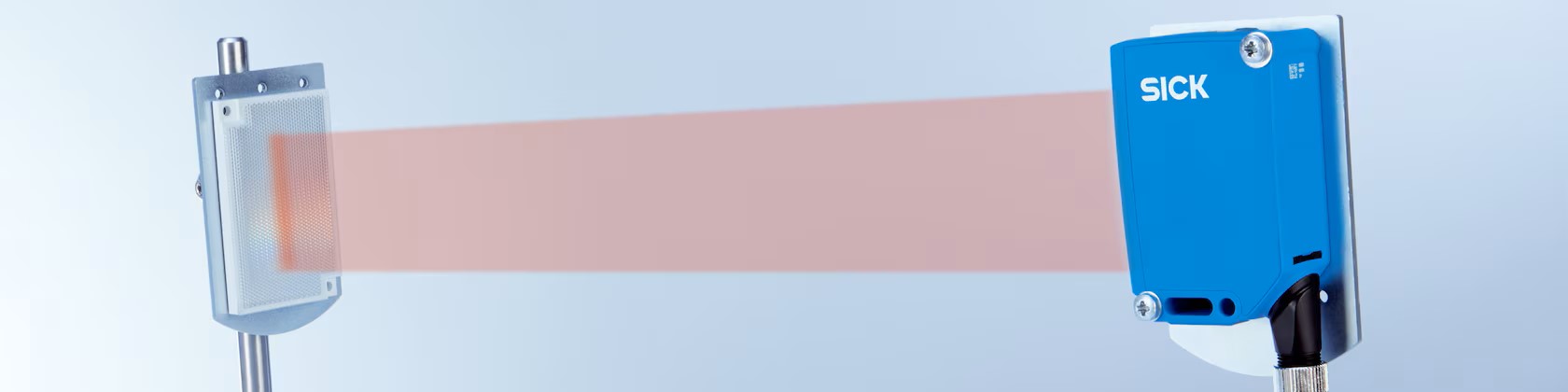

Photoelectric sensor with light array for detecting flat objects

Photoelectric sensors from the RAY26 Reflex Array product family enable reliable object detection of flat objects as well as fast commissioning. When combined with a reflector, the photoelectric sensors also detect small, flat, transparent or uneven objects from a size of 3 mm. Within a 55 mm-high uniform light array, the sensors detect the leading edge of the respective object for this purpose. This means that even perforated objects can be reliably detected without multiple switching.

RAY26 Reflex Array AT A GLANCE

Benefits

-Reduce overall costs by up to 50% compared to solutions with separate sender and receiver housings

-Reliable, position-independent detection of very flat objects

-Productivity increase thanks to reliable object detection (regardless of object property) and prevention of multiple switching (for perforated, non-uniform objects)

-Quick and easy optical alignment, commissioning and monitoring

-Reduction of downtime of conveyor systems

Features

-Sender and receiver in a single housing, combined with a reflector

-Detection of objects > 1 mm or > 3, 5, 10 mm, depending on the detection height

-ASIC from SICK

-Visible uniform light array (PinPoint LED)

-AutoAdapt technology (predictive maintenance) and conveyor belt suppression

ADVANTAGES

Simple alignment and reliable object detection

Simple alignment and reliable object detection

The RAY26 Reflex Array photoelectric sensor has a uniform, highly visible light band. The photoelectric sensor can be aligned quickly and easily thanks to this light band. After alignment, only teach-in is needed before the sensor is ready for object detection.

Save valuable time during commissioning thanks to the quick alignment and easy adjustment of the sensor

Predictive maintenance thanks to the transmission of maintenance signals

Predictive maintenance thanks to the transmission of maintenance signals

During operation, blue LEDs indicate the degree of contamination of the sensor and reflector. The integrated IO-Link technology enables quick and reliable transmission of these maintenance signals to the controller (PLC). This means maintenance and cleaning of the sensor can be planned at an early stage, avoiding unplanned downtime.

Prevent unplanned downtime with the help of predictive maintenance

Conveyor belt suppression

Conveyor belt suppression enables gradual deactivation of the detection zone (A) right above the conveyor belt. This suppresses the interference of the conveyor belt that causes the sensor to switch during system operation.

https://youtu.be/EZ-9tcrFGmI

Conveyor belt suppression, manually

https://youtu.be/ouxHvel19Zg

Conveyor belt suppression, via IO-Link

Ensure plant availability quickly and easily with conveyor belt suppression

View more about RAY26 Reflex Array on main site