deTec

Specifications

Details

Because we take safety to the next level

The intelligent deTec safety light curtains are ideal for the protection of hazardous areas, entrances, and hazardous points. Modern technologies such as NFC and IO-Link with their diverse functionality increase the level of automation and thereby productivity. The result: Simple on-site diagnostics, fast commissioning, and comprehensive data for automating downstream processes. Furthermore, the flexible connection concept in combination with the uniform housing design ensures low cabling, installation and configuration costs. The required functions are activated without software via the matching system plug. Thanks to different enclosure ratings as well as variants for explosion-hazardous areas, deTec also provides solutions for applications in harsh environments.

deTec AT A GLANCE

Benefits

-Benefit from a productivity boost and short downtimes thanks to the innovative diagnostic options

-Increase the level of automation and process transparency of your systems with IO-Link

-The reliable object pattern recognition without external signals or devices ensures a cost-effective and compact machine design

-Muting offers productivity and safety in human-material differentiation

-High availability: smart presence detection prevents unwanted switch-offs

-Easy commissioning and configuration without the need for software saves you time and money

Features

-NFC diagnosis and smartphone app

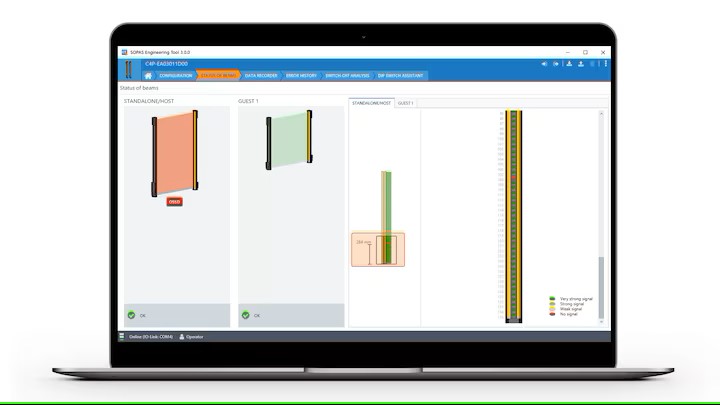

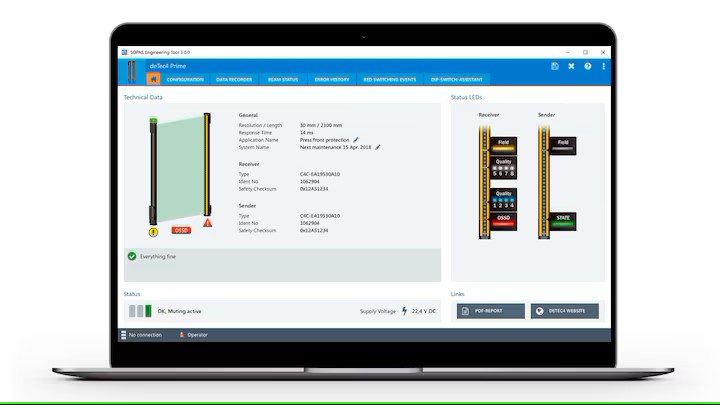

-Diagnostics and automation via IO-Link

-Object pattern recognition using Smart Box Detection

-2-signal muting

-Smart presence detection

-Configuration of all functions without software

-Reduced resolution: 1 or 2 beams

-Different enclosure ratings as well as variants for use in explosion-hazardous areas

ADVANTAGES

Intelligent safety light curtain for high productivity

Intelligent safety light curtain for high productivity

Whether you are in the automotive industry, mechanical engineering or consumer goods production: high productivity and a high degree of flexibility and automation are decisive competitive advantages in the era of digitalization. The deTec safety light curtain helps operate machines and systems economically with intelligent functions. In addition to the extremely rugged housing and the innovative diagnostic functions, deTec impresses with easy connection, configuration and alignment.

https://youtu.be/qVziQvSMuuE

Intelligent functions

Save space and costs when designing machines. Using Smart Box Detection, you can dispense with the use of external signals or devices.

https://youtu.be/lqoOrNJr1Hw

Fast commissioning

Here you can see in five simple steps how to quickly mount and align the deTec.

Simple diagnostics

Take advantage of comprehensive on-site diagnostics via smartphone app and NFC interface.

Invest in a secure and profitable future with deTec

The deTec unites safety and automation in one sensor

The deTec unites safety and automation in one sensor

In addition to a high level of safety, intelligent safety sensors also offer a wide range of automation options. The deTec4 product variant not only protects people, but also provides valuable data for downstream process steps via IO-Link. This means you don’t need as many sensors. The sensor also makes a valuable contribution to the mobile maintenance of your machines or plants.

Versatile automation options

Use extensive process data for downstream automation processes, e.g. for height measurements.

More efficient cause analysis

Comprehensive service data allows you to perform predictive maintenance, e.g. when sensors start to get dirty, and for quick and easy cause analysis.

Increase the level of automation and process transparency of your machines and plants

From a single mold and always flexible

From a single mold and always flexible

The deTec safety light curtain is ready for use in no time at all. Thanks to the uniform housing and mounting concept as well as standard cables, the device is always equally easy to implement in the machine design.

Flexible connection design

Thanks to its high modularity, the deTec allows for functions to be activated quickly and easily by means of the appropriate system plug for each application, and completely without software.

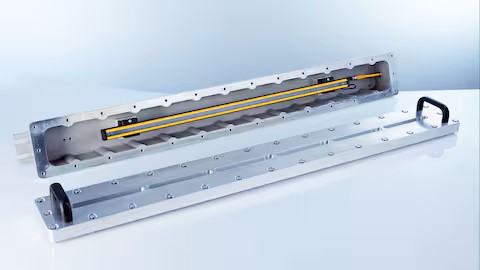

Uniform housing and mounting concept

deTec and brackets are tailored to one another and flexible to use. Housing profile, end caps, and brackets are all from a single source and offer a secure hold as well as many alignment possibilities.

Benefit from minimal cabling, installation and configuration work

Safety light curtains for the strict requirements of your industry

Safety light curtains for the strict requirements of your industry

Depending on the area of application, the topic of safety encompasses other aspects: in food production and processing, hygiene standards must also be taken into account. In explosion-hazardous areas, it is a matter of compliance with explosion protection standards. In the machine tool industry, the resistance of the safety light curtain to the chemicals in coolants, lubricants and cleaners often plays a decisive role. When protecting machines and systems, there are also high requirements for shock and vibration resistance and thus sensor availability.

High hygiene standards

With its easy-to-clean housing made of food-safe plastic and stainless steel, the deTec IP69K is ideal for protecting washdown zones.

Explosive areas

Different Ex zones can be protected by different deTec variants.

Resistant to chemicals

The deTec HG variants with a front screen made of chemically-hardened float glass is especially resistant to coolants and lubricants.

Take advantage of the wide range of applications of the deTec

View more about deTec on main site