OD Value

Specifications

Details

Simply accurate measurement

The OD Value allows for an easy, precise and economical solution of measuringtasks. It detects even small deviations in dimension, shape, position or excentricity directly in the machine, contactless, precise and during running operation. OD Value convinces with its main features: reliable, user-friendly, effective, universal and efficient. The ideal solution for everyone, who needs to check and verify quality regulary and directly in the process.

OD Value AT A GLANCE

Benefits

-Reliable measurement independent of surface, minimizes machine downtime

-Extremely simple sensor teach-in makes setup faster and more costeffective

-Minimal space requirements and less wiring due to its compact, standalone design

-Many measurement ranges and output interfaces make it ideal for cost-effective integration into any production environment

-Low investment costs make consistent, regular quality inspection possible

-Non-contact measurement technology from a safe distance allows the inspection to be carried out directly during the production process

-Wear and damage-free inspection, due to non-contact measurement

Features

-Several measurement ranges from 26 mm ... 34 mm to 100 mm ... 500 mm

-CMOS receiving element for measurement independent of surface

-Easy, LED-based user and teach-in concept

-Wide range of models and a wide range of standard interfaces

-Laser technology for precise measurement of very small objects

-Compact stand-alone device

-Excellent price-performance ratio

ADVANTAGES

.jpg) Precision meets quality

Precision meets quality

With expert-developed intelligent measurement technology which proves its worth in industrial applications time and time again, SICK offers the solution to any challenge which demands maximum measurement accuracy and quality. A pioneering spirit founded on our years of experience and our own innovations in optical sensor technology. We ensure efficient processes while fulfilling the demands of even complex measuring tasks – regardless of surface, diameter, thickness, or width, and regardless of whether an object is to be positioned or measured. This is how we ensure that your products are every bit as perfect as you want them to be. Moreover, SICK’s measurement technology supports quality assurance processes and delivers cost-saving benefits.

A point of light is projected onto the measuring object. The light reflected is captured by a light-sensitive receiver at a specific angle. Based on the angle between the send and receive direction, the position of the object is then triangulated (from the Latin “triangulum” = triangle).

.jpg)

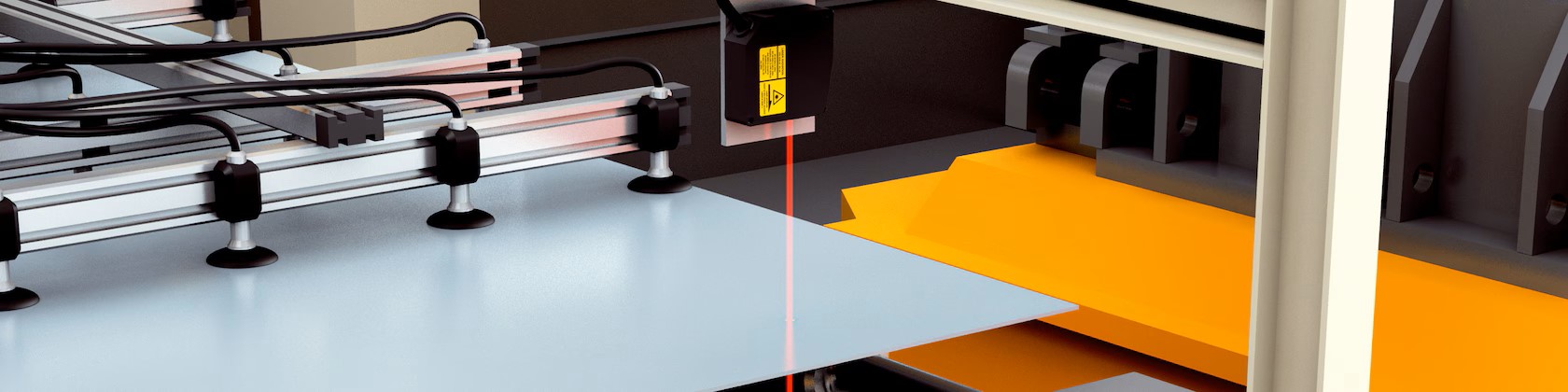

High flexibility at short distances

High flexibility at short distances

Even where measuring distances are short, SICK’s displacement measurement sensors are immensely versatile. They meet the very highest requirements placed on quality and precision in a wide range of measuring tasks and applications.

Checking components

The OD Value distance sensor is lightweight and can therefore be mounted directly on the placement head. It measures the height of the components and application of solder paste in advance and delivers the missing Z data to the 2D vision system of the placement head.

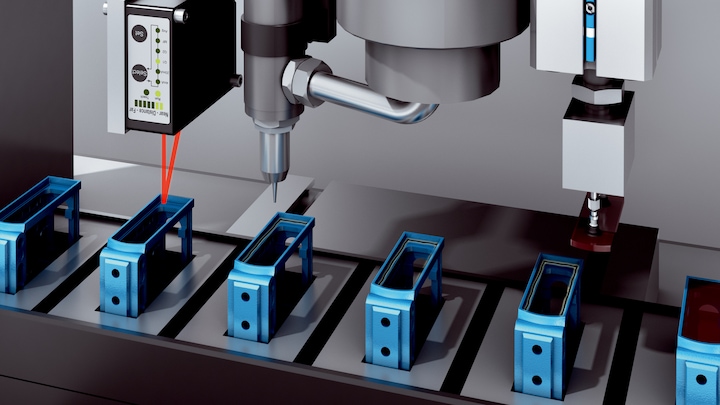

Positioning dispensing needles with precision

For dispensing processes with high repeatability, the absolute distance between dispensing needle and object is very important. The OD Value displacement measurement sensor measures the distance to the object down to the last micrometer and is very cost effective. Thanks to the light spot with a small diameter, it is perfectly suited for measuring the smallest structures.

Measurement of the wane

Two highly precise OD Value displacement measurement sensors mounted opposite each other calculate the exact profile of a board and detect the position of the wane. The vision integrator uses the data during scanning and interpolates the differential between the profiles for optimizing the board, which is then trimmed in the saw.

Precise positioning

Approach the right position every time with a high level of accuracy. With displacement measurement sensors from SICK, grippers and other tools can be positioned exactly without any contact, and with maximum repeatability. Typical applications are "Robot guidance for windshield installation" or "High-accuracy positioning of carriages". Typical industries for the OD Value are robotics, handling and assembly and automotive and parts suppliers.

OD Value stands for maximum all-round reliability and provides exact measurements of countless different materials and surfaces.

SICK LifeTime Services

SICK’s services increase machine and plant productivity, enhance the safety of people all over the world, provide a solid foundation for a sustainable business operation, and protect investment goods. In addition to its usual consulting services, SICK provides direct on-site support during the conceptual design and commissioning phases as well as during operation.

The range of services not only covers aspects like maintenance and inspection, but also includes performance checks as well as upgrades and retrofits. Modular or customized service contracts extend the service life of plants and therefore increase their availability. If faults occur or limit values are exceeded, these are detected at all times by the corresponding sensors and systems.

.jpg)

Consulting and design

Application-specific advice on the product, its integration and the application itself.

.jpg)

Commissioning and maintenance

Application-optimized and sustainable ─ thanks to professional commissioning and maintenance by a trained SICK service technician.

.jpg)

Service contracts

Extended warranty, SICK Remote Service, 24-hour helpdesk, maintenance, availability guarantees and other modular components can be individually combined on request.

View more about OD Value on main site